InterMet Africa offers full turnkey electronic contract manufacturing from prototypes right through to high volume production. Services include part procurement and management, assembly, testing, mechanical integration through to packaging and shipping.

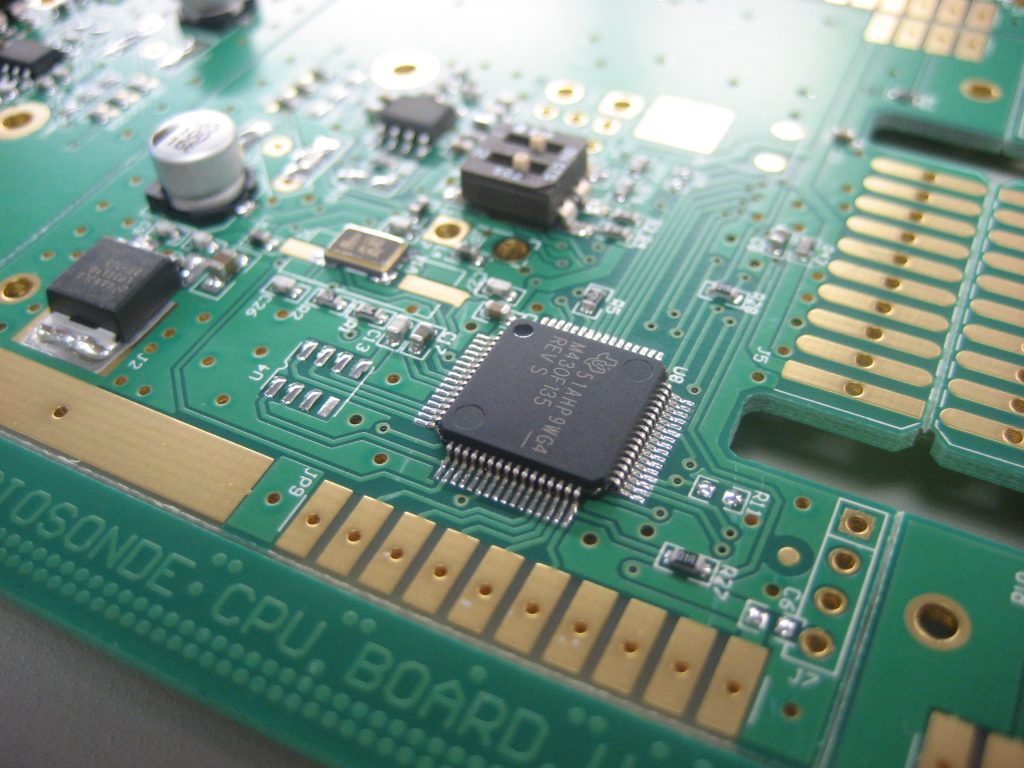

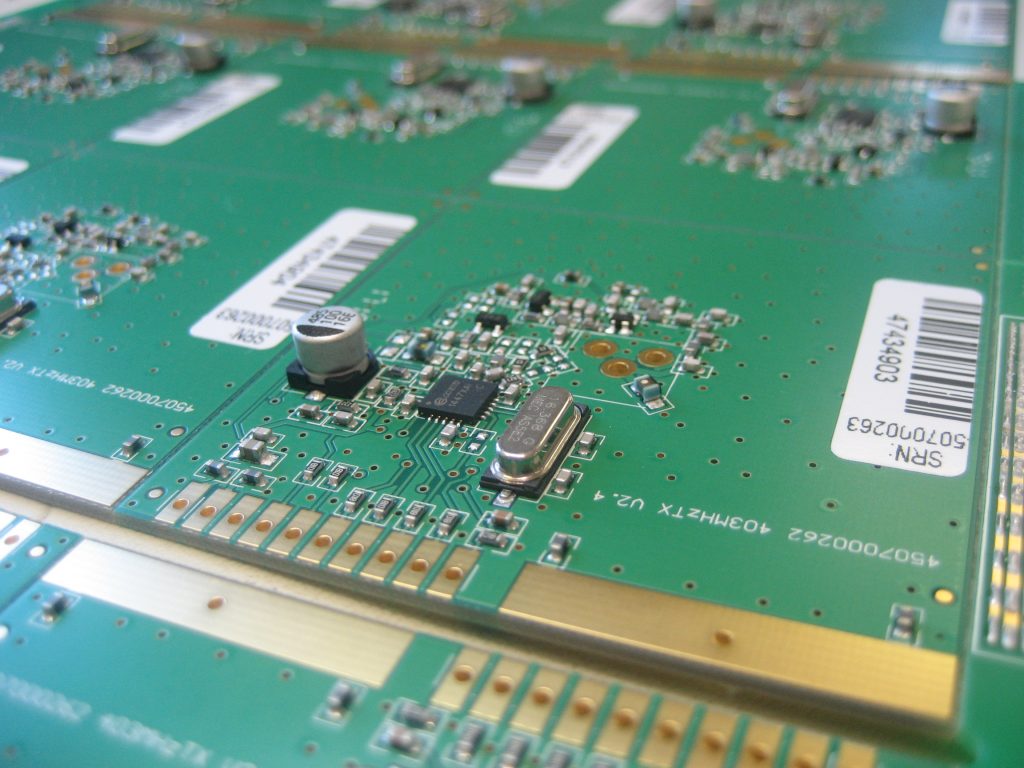

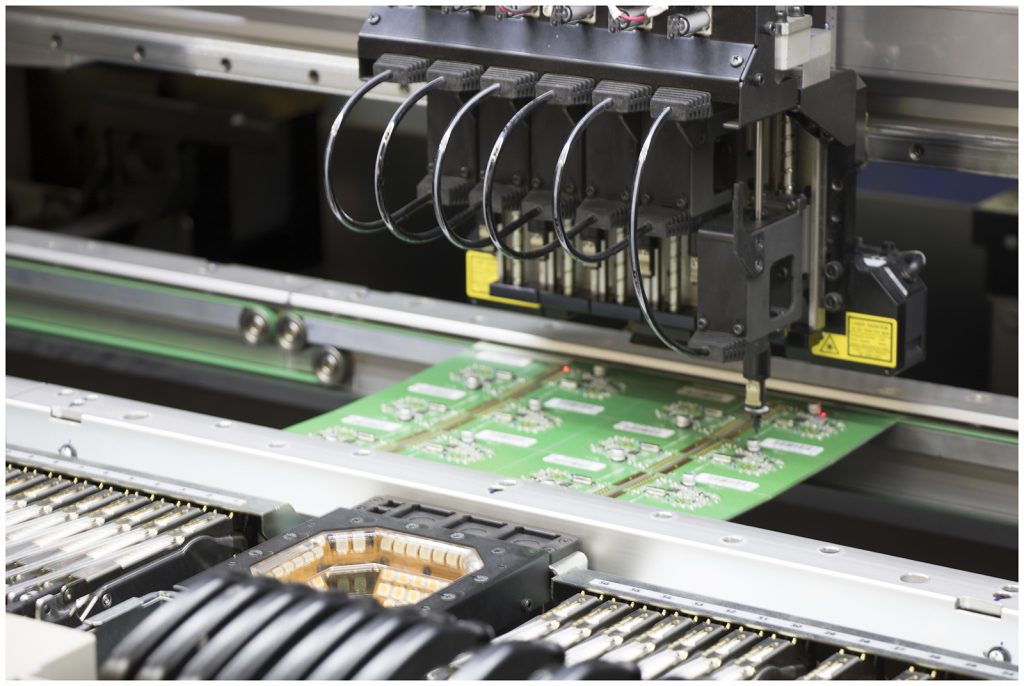

Surface Mount Assembly

We have Yamaha pick & place machines which are renowned for their high speed accuracy. Our machines can place components from 0201 chips and up to 90mm components. Each component is photographed prior to placement and calculates on the fly any variances in the pickup offsets. This allows for placement accuracy of ±0.04mm.

We have DEK stencil machines which include their patented Hawk-eye. This allows for automated paste inspection practically eliminating paste related faults.

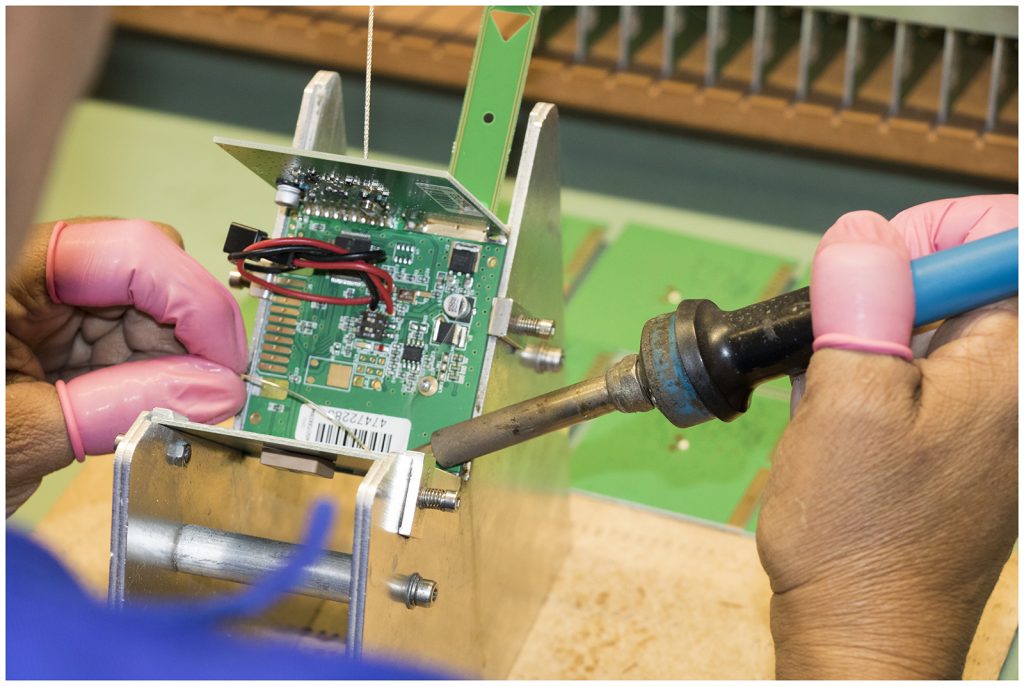

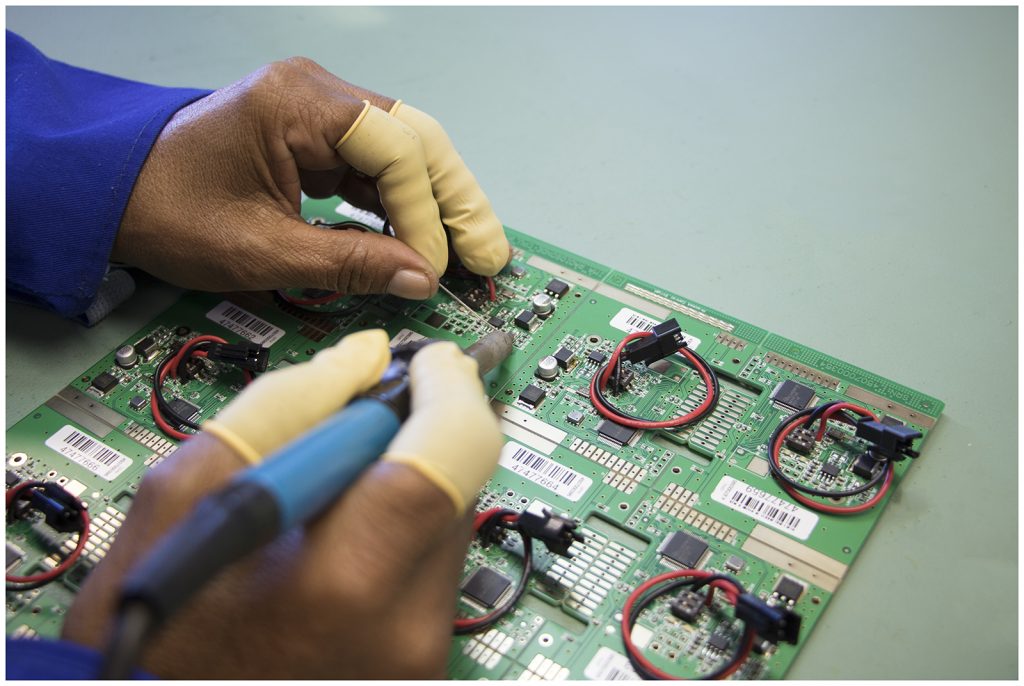

Through-Hole & Hand Assembly

Currently we solder all through-hole components by hand. This however has zero impact on quality or lead times to customers. We have multiple skilled solders on hand to tackle any requirement.

Board Washing

We have ultrasonic cleaning baths to remove any excess solder flux. This ensures that there are no contaminates left on the circuit boards after manufacture.

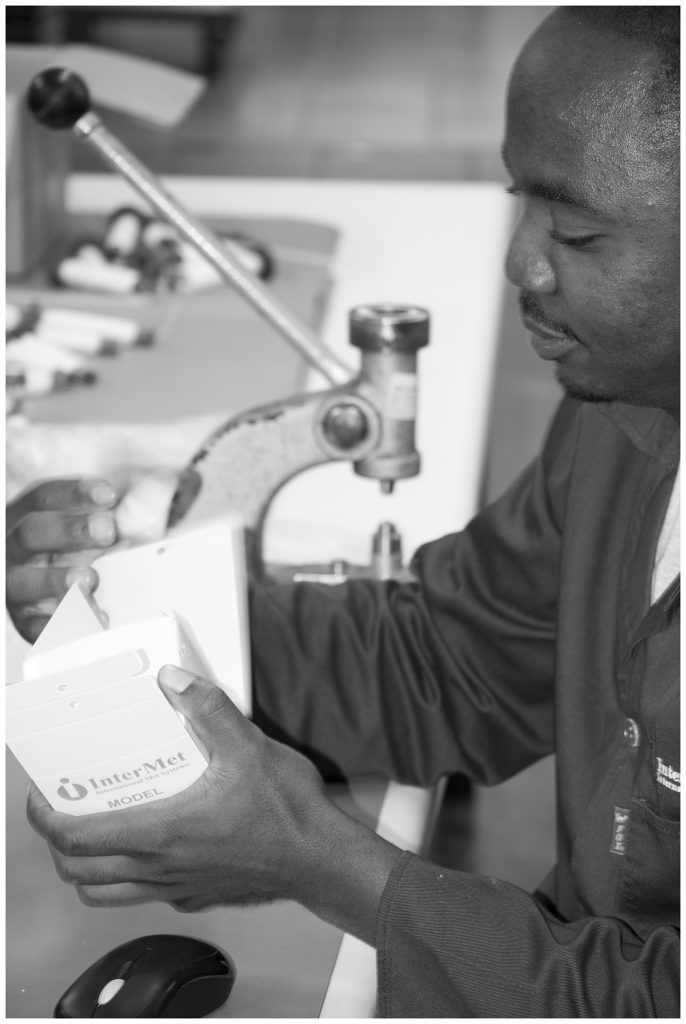

Inspection

We have a Cyberoptics automatic optical inspection machine as well as high end optical microscopes for inspection of all boards from 1-offs to high volume runs.

Conformal Coating

We have selective dispensing machines as well as manual mask and conformal processes. Conformal coating protect circuit boards against moisture, dust and other contaminants that may lead to reduced life span.

Testing

We have multiple testing stations pre-setup with standard test equipment from simple power supplies to oscilloscopes, spectrum analysers and even GPS repeaters . Our technicians are qualified to program and test analogue, digital and even RF circuits.

Procurement

We stock a wide range of common value passive components as well as offer the facility to procure and stock components on behalf of our customers. We have a detailed ERP software package which accurately keeps track of inventory. We have a vast list of suppliers and distributers both locally and internationally.

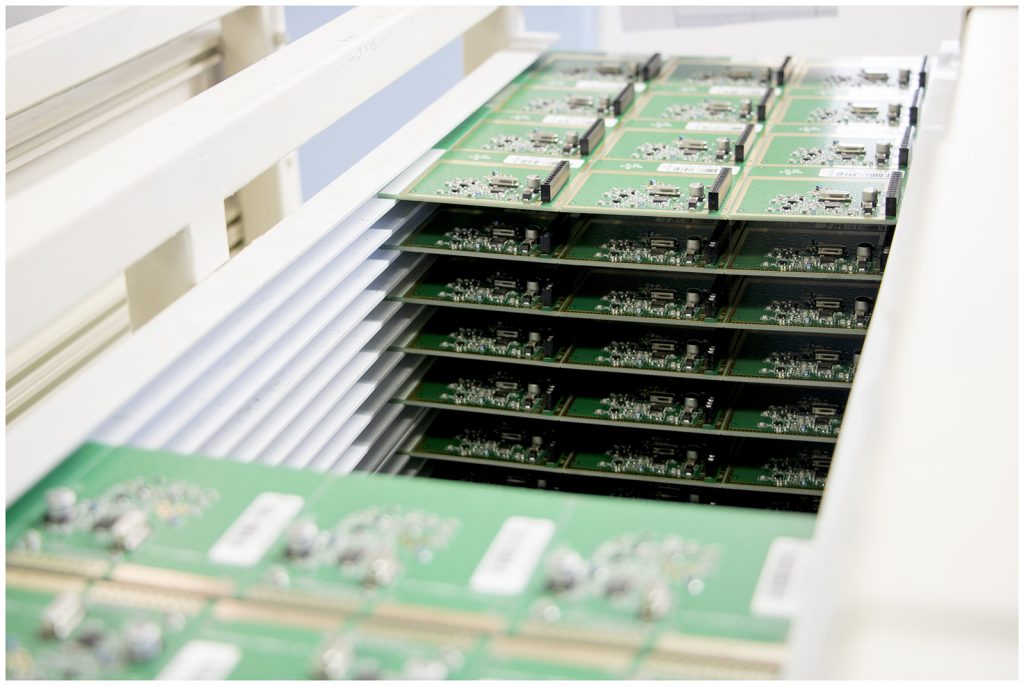

Version Control

All manufactured items are loaded onto our ERP software package and thus allows us to accurately keep track of board versions and batches through to board serialisation.

Standards

Our factory is strictly RoHS compliant. We follow IPC-610 standards and work in an ESD controlled environment. We have a comprehensive ISO9001 management system that ensures that top quality is maintained at all times.

Support

We have a full complement of design engineers (both mechanical and electronic) on site to offer product design support.

Enviromental Testing

We have Thermotron environmental chambers cabable of temperature and/or humidity cycling boards from -68°C to +180°C and from 10%RH through to 100%RH.